Why your business will fall by the wayside without the right combination of RTLS technologies

9. April 2025

Production planning software

15. July 2025

Returnable transport items management - Efficient solutions for optimized logistics

Effective container management is crucial for companies that want to optimize their logistics processes and reduce costs. With the innovative solutions from INDUTRAX, companies can monitor their material flows in real time, minimize losses and increase the efficiency of the entire supply chain. Here you can find out how modern container management works, which technologies are used and what benefits it offers your company.

Definition: What is returnable transport items management?

Returnable transport items management refers to the systematic management, control and tracking of reusable and transport containers within a company's logistics and production processes. The aim is to ensure complete transparency regarding the location, condition and availability of containers in order to avoid losses, reduce costs and optimize the efficiency of the supply chain.

Modern returnable transport items management systems use digital technologies such as RFID, GPS or RTLS (Real-Time Locating Systems) to record the material flow in real time and enable automated processes. This contributes to a more sustainable use of resources and improves operational efficiency.

The advantages and goals of intelligent returnable transport items management

- Reduction of container losses: Thanks to real-time location tracking, you always know where your containers are.

- Optimization of inventory management: Prevent overstocking or bottlenecks through precise data analysis.

- Automated processes: Seamlessly integrate returnable transport items management into your existing logistics and ERP systems.

- Cost savings: Significant savings can be achieved through more efficient use and longer container service life.

- Sustainability: Reduce unnecessary transportation routes and promote resource-saving logistics processes.

- Increased transparency: Complete documentation and digital traceability of all container movements.

- Avoiding production and delivery bottlenecks: Ensuring that sufficient containers are always available so as not to interrupt operational processes.

- Improved planning: Data-based analyses enable better forecasting of future requirements and optimization of production processes.

Returnable transport items management: why an intelligent solution is essential

Returnable transport items management plays a central role in industry, especially in production and logistics processes. Inefficient container management can lead to losses, bottlenecks and increased costs. Companies often face challenges such as:

- Lack of transparency about the location of containers

- Time-consuming manual search processes

- Unnecessary new purchases due to losses

- Insufficient maintenance and premature wear

Real-Time Location Systems (RTLS) allow containers to be tracked seamlessly, giving companies an accurate overview of their stock at all times and enabling them to make their processes more efficient.

Returnable transport items management with RTLS: The future of logistics

The use of RTLS technologies(Real-Time Location Systems) is revolutionizing container management. Our software uses various tracking technologies such as GPS, RFID, UWB or BLE to record the location and status of containers in real time. This enables automated inventory management, reduces search times and prevents bottlenecks or overstocking.

Location tracking made easy: the best methods for precise location determination

Imagine knowing where your materials, tools or production aids are at all times. No chaos, no delays, just maximum planning and precision.

How does RTLS work in returnable transport items management?

- Real-time data collection: sensors and tags are attached to containers to monitor their location and status.

- Data transmission: Data is sent to central software via various technologies such as RFID or UWB.

- Analysis & visualization: The software processes the data and presents it clearly in dashboards.

- Automated processes: Measures can be taken automatically in the event of deviations or bottlenecks.

This intelligent control leads to a more efficient container cycle and significantly reduces manual effort.

Which technologies support returnable transport items management?

- RFID (Radio Frequency Identification): This technology enables the automatic identification of containers at certain points in the long supply chain, such as at the supplier's outgoing goods department. It is ideal for monitoring transportation between different locations.

- UWB (Ultra-Wideband): Offers the highest precision in real-time location tracking and is particularly suitable for in-plant logistics in large production halls and warehouses.

- BLE (Bluetooth Low Energy): Energy-efficient solution for cost-effective location tracking, especially for applications that map container transports in outdoor and indoor areas.

- GPS: Ideal for tracking containers in extensive outdoor areas, e.g. for transportation logistics or large storage areas.

Returnable transport items management is particularly important for these industries

In general, any company that produces, stores or transports goods can benefit significantly from well thought-out returnable transport items management. It is particularly essential for industries with complex supply chain processes, including:

- Production: Ensuring a smooth material flow in manufacturing processes

- Retail: efficient storage and fast availability of goods

- Automotive industry: Just-in-time supply chains and complex manufacturing processes require optimized container cycles

- Medical technology: Precise tracking and hygienic handling of sensitive goods

- Hydraulics industry: Organization and transport of heavy components with high safety requirements

- Electronics industry: Protection of sensitive components through targeted container tracking

- Food industry: Ensuring freshness through safe availability of containers during packaging.

- Transportation and warehousing: Efficient use of storage space and smooth distribution processes

- Supply chain management: digitalization and tracking of containers to optimize logistics processes and reduce costs.

The specific requirements vary depending on the industry, but one thing remains the same: efficient container management ensures optimized processes and greater cost-effectiveness. Let our experts advise you to find the best solution for your company!

Best practices for successful returnable transport items management

1. introduction of digital inventory management

The integration of digital returnable transport items management reduces sources of error and improves the traceability of all movements.

2. selection of the right tracking technologies

Not every technology is suitable for every application. A detailed analysis of the operational requirements is essential.

3. automated workflows and processes

By automating bookings, reminders and alerts, bottlenecks and losses can be proactively avoided.

4. regular maintenance and inspection

Continuous monitoring of the container condition extends the service life and minimizes unforeseen failures.

INDUTRAX - Your partner for intelligent returnable transport items management

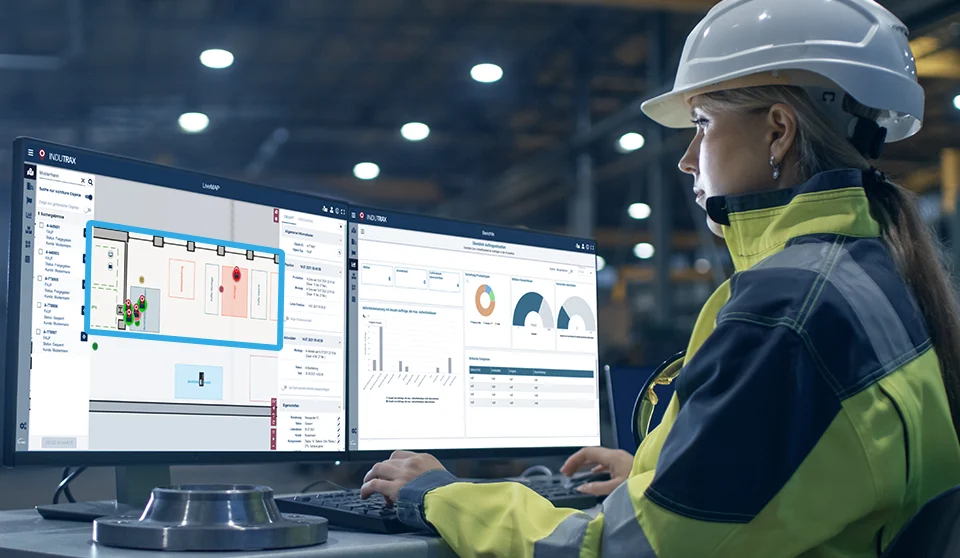

We offer tailor-made solutions for companies that want to modernize their returnable transport items management and make it more efficient. Our modular RTLS systems can be flexibly integrated into existing structures and ensure seamless digitalization of container tracking.

Why INDUTRAX?

- Many years of experience in the implementation of innovative RTLS solutions

- Individual advice and customized solutions

- Scalable systems that grow with your company's requirements

- Simple integration into existing IT and ERP systems

Sophisticated returnable transport items management with Real-Time Location Systems offers companies numerous benefits, from reduced losses to optimized processes. INDUTRAX provides the right technologies and solutions to take your logistics to the next level.

Benefit from the advantages of innovative returnable transport items management and optimize your logistics processes sustainably. Contact us for an individual consultation and take your returnable transport items management to the next level now.

Your contact person

Dr. Andreas Schürzinger

Principal Consultant IoT

Let's work together to find your optimum locating solution!

With our expertise in tracking system optimization, we analyze your specific requirements and determine the right combination of tracking technologies that can transform your production and logistics processes.Error: Contact form not found.