Seamless and future-proof tracking solutions with standards – how omlox combines tracking technologies

27. March 2025

Returnable transport items management

13. May 2025

Why your business will fall by the wayside without the right combination of RTLS technologies

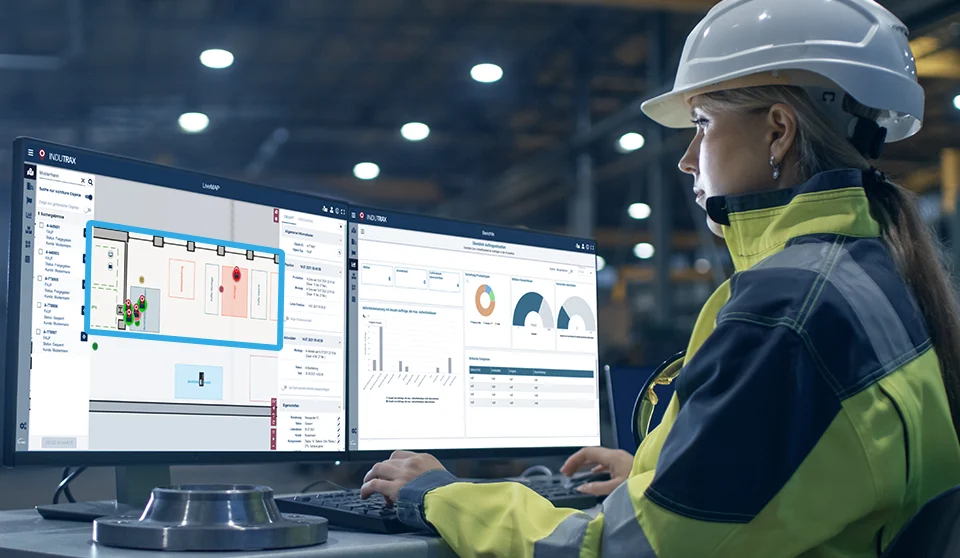

The implementation of RTLS systems (Real-Time Location System) finally brings light into the darkness of your logistics and production processes. The key to success? A clear vision of how location solutions can specifically optimize your daily processes.

An innovative software platform that can be flexibly adapted to different application scenarios is crucial. Instead of just comparing tracking systems, you should focus on how you can sustainably increase the efficiency of your processes with the right software. In this article, you will learn how RTLS technologies, combined with smart software, can revolutionize your processes in the long term.

Why a combination of RTLS technologies is the key to success

By cleverly combining different RTLS technologies, you can increase efficiency and transparency in your production. This results in cost-effective, reliable and future-proof solutions for precise and flexible process control. Once you have clearly defined your process support goals, choosing the right RTLS solution becomes easier.

Pay attention to the following key factors:

- Reliability & responsiveness of the position calculation, tailored to the application

- Total costs (investment & operation)

- Future-proof through the use of standards, flexible interfaces and modular software modules

- Scalability of the overall system

But beware! Although a single RTLS technology often fulfills your technical and functional requirements in the short term, the initial investment is often high, and profitability is not always guaranteed in the long term.

The solution is a software platform that combines different tracking technologies and is tailored to your exact needs. Here are some applications with common combinations that you should consider to find a tracking solution suitable for your business.

Indirect location tracking: perfect for controlling material flows

“Indirect location tracking” is ideal for tracking a large number of objects or devices. By combining identification, location tracking and smart software, information is quickly brought together. Inexpensive barcodes/QR codes or RFID transponders are attached to the devices to be tracked and their position is determined by the reader at the time of the identification process.

Flexible software integrates and plausibilizes from different systems, controls and documents transports and provides clear instructions via mobile applications. This means that people on industrial trucks receive immediate feedback. Uncertainties in automatic data collection are quickly resolved. Intelligent functions such as inventory management also resolve conflicts with undocumented transports by transferring the position of located hand scanners directly to the identified goods - for maximum transparency.

UWB/BLE RTLS & identification via barcode / QR code

Industrial trucks are tracked via UWB or BLE RTLS so that their exact location can be determined via radio signals. When material is picked up on the fork, employees can identify it quickly and easily using a handheld or back-of-hand scanner with a barcode and QR code. The distance of the transported material is then automatically taken from the location tracking of the FFZ. As soon as the material is set down, the employees confirm this by pressing a button on their mobile device. This time marks the end of the transport route and the position of the material is recorded. Ideal for production environments in which a lot of goods are moved indoors - whether by industrial trucks or forklift trucks.

LiDar / Marker-based camera positioning & RFID

Industrial trucks locate themselves automatically using LiDar or marker-based camera systems. As soon as material is picked up onto the fork, it is automatically identified via RFID. The software then automatically transfers the location of the transported material from the FFZ's location tracking system. The delivery is recorded via the fork position sensor or RFID reader and the position of the transported material is recorded. Ideal for production environments that include both mixed indoor and outdoor areas, with numerous goods movements through predominantly FFZs.

Location tracking made easy: the best methods for precise location determination

Imagine knowing where your materials, tools or production aids are at all times. No chaos, no delays, just maximum planning and precision.

Direct location tracking: Seamless combination for controlling orders

“Direct location tracking” is ideal for objects that move or are moved independently or unpredictably. Different technologies are used depending on the environmental conditions and specific requirements. Smart software bundles the collected data, prioritizes incoming messages and thus ensures reliable location determination.

Location tracking of orders using BLE (Bluetooth Low Energy) beaconing or BLE RTLS

Enables very cost-effective and simple presence detection with wireless beaconing infrastructure and precise location tracking with wired BLE AOA receivers. Ideal for tracking goods and devices in different environments with varying accuracy requirements. In a production hall, for example, a distinction can be made between dwelling in buffer and workstation areas, while in a warehouse the presence of a component is simply recorded.

Location tracking of vehicles using GPS or BLE RTLS

Provides cost-effective and easy outdoor location tracking using GPS and precise indoor location tracking using wired Bluetooth AOA receivers. Ideal for tracking vehicles in large factory environments with indoor and outdoor areas.

For a basic overview of the benefits of tracking technologies, we recommend taking a look at our blog post on The best methods for precise location tracking.

How do you find the right combination of RTLS technologies for your company?

Choosing the right RTLS solution depends on various factors: the type of objects you want to track, the conditions in which the technology is used and the specific requirements of your production and logistics processes.

To find the right combination, you should consider the following steps:

1. define objectives and requirements: What type of objects and how many should be tracked? Do you need a precise location determination or is a general attendance recording sufficient? Which processes should be optimized?

2. consider technological requirements: Do you need a solution for indoor or outdoor use? Is high accuracy required or is rough positioning sufficient? Should the solution be scalable and be able to be expanded in the future?

3. cost-benefit analysis: What is your budget for implementing and operating the RTLS system? A customized solution that combines different technologies offers greater benefits in the long term.

4. ensure software integration: A flexible software platform that combines different technologies and processes the collected data is crucial for the efficient use of RTLS technologies.

Practical example: This is how an agricultural machinery manufacturer optimizes its production with the combination of GPS and BLE RTLS:

The initial situation: time wasters and a lack of transparency

A leading agricultural machinery manufacturer was faced with the challenge of moving tractors in the end-of-line and rework processes in large halls and outdoors, but vehicles could not be found immediately.

Without a precise localization solution, this led to:

Lack of transparency:

Lack of transparency:

High search effort:

The company needed automated location tracking to gain full visibility and control over the entire process. A combination of GNSS/GPS with Abeeway for outdoor location tracking and Quuppa BLE RTLS for real-time location tracking on the production floor was the solution.

The solution: seamless location tracking for indoor & outdoor use

GNSS/GPS for outdoor tracking:

BLE RTLS for indoor tracking:

Thanks to this combination, the company now knows where every vehicle is at all times.

Result: Immediately measurable optimization

No more searching

Better response times

Higher productivity

With the combination of GNSS/GPS and BLE RTLS, inefficient search processes are a thing of the past. No more guesswork, no more manual searches - just clear, real-time location tracking that ensures maximum efficiency. This solution is an example of how tracking systems are driving Industry 4.0 forward.

Conclusion: The right combination of RTLS technologies makes all the difference

It is clear that there is no universal solution - the optimum application depends on your individual requirements, environmental conditions and budget. Maximum efficiency is achieved through the combination of suitable RTLS technologies and appropriate software. The right combination of technologies ensures maximum precision and flexibility in real time at minimum cost. This allows you to optimize your processes and remain optimally positioned for future requirements.

Your contact person

Dr. Andreas Schürzinger

Principal Consultant IoT

Let's work together to find your optimum locating solution!

With our expertise in tracking system optimization, we analyze your specific requirements and determine the right combination of tracking technologies that can transform your production and logistics processes.Error: Contact form not found.