Returnable transport items management

13. May 2025

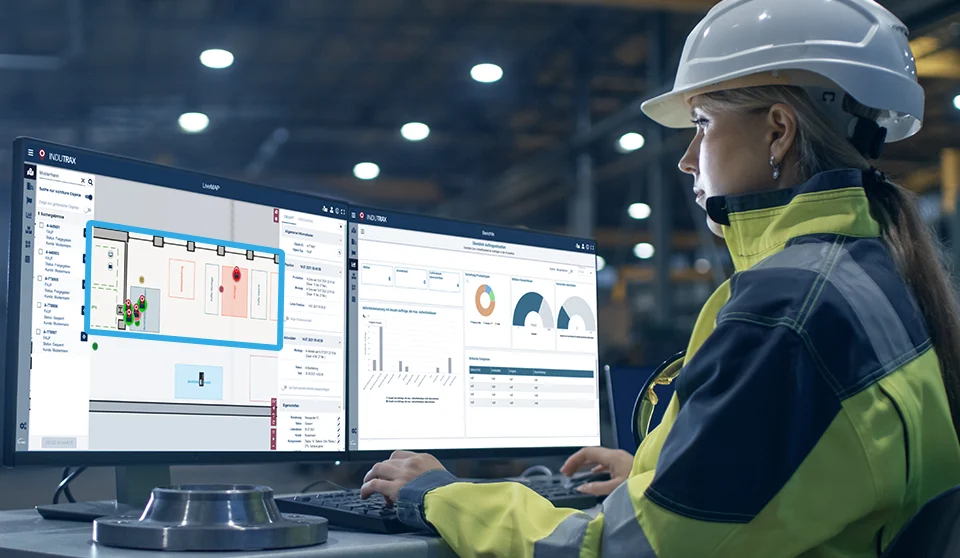

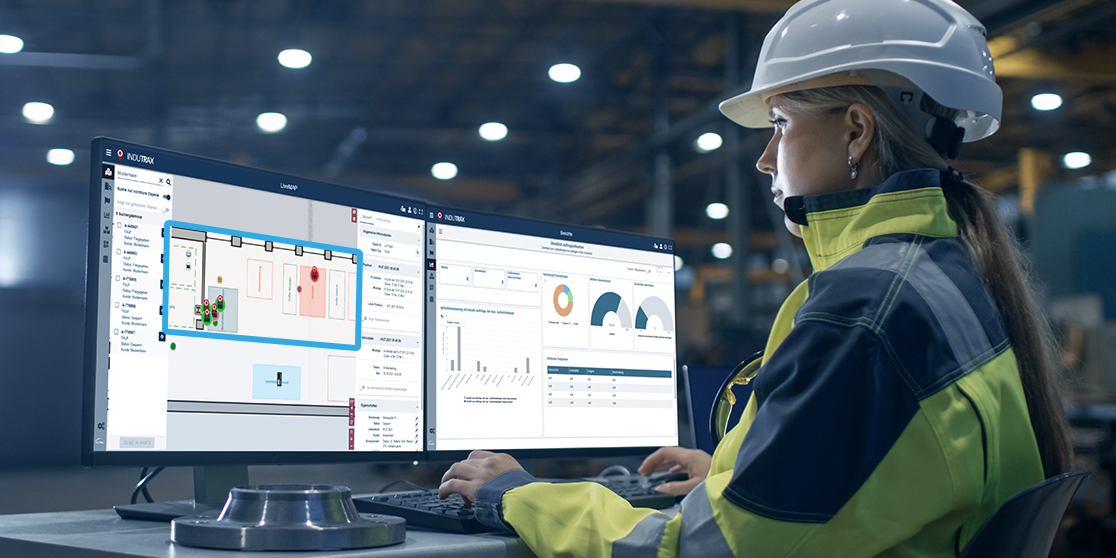

Production planning software: Reality instead of theory with INDUTRAX

Precise planning is essential in modern production companies. However, traditional production planning software reaches its limits when it is based on assumptions rather than real-time data. The INDUTRAX Application Environment does not provide a planning function in the classic sense - it provides the reality on which your planning is based.

Our software is not designed to manage machine occupancy or maintenance schedules. Instead, we record movements and material flows in the production environment in real time. In this way, we create an objective data basis that you can use to make your production planning more informed and continuously improve it.

How INDUTRAX optimizes your production planning processes

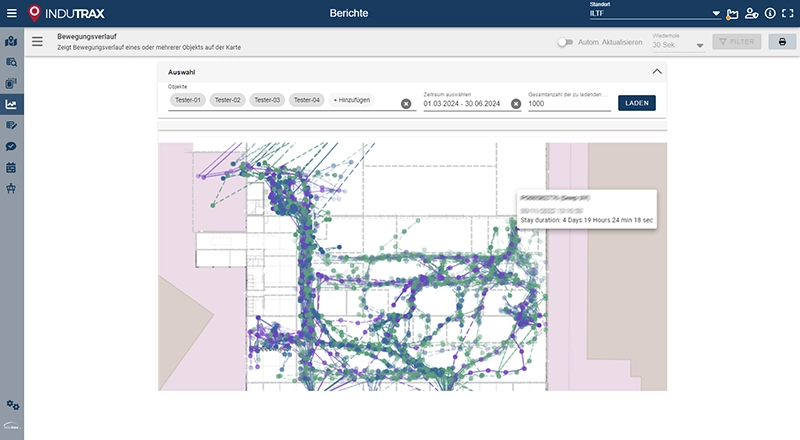

Planning is only as good as the data on which it is based. With INDUTRAX, you can see what is actually happening at Shop Floor - not just what was planned. This allows you to recognize deviations, bottlenecks or unnecessary routes immediately and respond promptly. Instead of searching for causes, you receive concrete indications of optimization potential.

A practical example: Our reference customer AAE was able to significantly improve its planning processes with the help of the recorded material flows - not through simulation, but through reality and a focus on material and movement around the machines.

The most important functions at a glance:

- Real-time tracking: seamless tracking of production orders, order batches, materials and load carriers

- Automated bookings: Reduction of manual entries and errors

- Digital order information: adaptable to the situation, available directly on the order

- Tracking of work in progress: less buffer, less space required, higher liquidity

- Continuous improvement: analysis of historical transaction data for process optimization

INDUTRAX complements your production planning - through transparency in ongoing operations

Our software is not a planning instrument, but an operational tool. It supplements existing systems such as ERP, MES and PPS with precise location and movement data. This enables us to make your production more transparent, efficient and responsive.

Who is INDUTRAX suitable for?

Companies with high product diversity, variable production or many manual processes benefit in particular. Whether in the automotive industry, electronics production or mechanical engineering - wherever real processes need to be better understood, we create the necessary transparency.

With our solution, you don't gain another planning screen, but a clear view of your production. Optimize your planning not theoretically - but based on the real processes in your production.

Find out more now and future-proof your production.

Advantages of INDUTRAX software for production planning

Our software is based on:

- Real-time transparency: clear overview of material flows and production steps

- Optimized processes: Reduction of bottlenecks and smooth processes

- Flexible modules: Adaptable to your company's specific requirements

- Seamless integration: linking with existing ERP and MES systems

- Maximum efficiency: automation and digitalization of your production planning

Why do production companies need real-time positioning systems?

Predictive and flexible production planning is only possible if up-to-date information from ongoing operations is available. Real-time localization systems (RTLS) provide this data directly from production - and thus create the basis for planning that is based on facts rather than assumptions.

RTLS enable the seamless tracking of materials, tools, products and means of transportation throughout the entire production environment. This results in the following advantages for production planning, among others:

- Reliable data basis: Location and movement data provide the actual status of individual production orders - planners recognize bottlenecks or delays at an early stage.

- Better allocation of resources: Transparency regarding available tools, materials and means of transportation means that deployment can be planned in a more targeted manner.

- Increase responsiveness: Real-time data enables short-term rescheduling, for example in the event of machine downtimes or material bottlenecks.

- Recognize optimization potential: Historical transaction data helps to identify and avoid planning errors or systematic delays.

- Greater adherence to schedules: If planners know where everything is and how long processes actually take, they can create more realistic and reliable production plans.

The INDUTRAX software provides a solution that combines real-time positioning technology with context-related data processing. This creates a transparent database on which well-founded planning decisions can be made - flexible, accurate and up-to-date at all times.

Location tracking made easy: the best methods for precise location determination

Imagine knowing where your materials, tools or production aids are at all times. No chaos, no delays, just maximum planning and precision.

Rely on future-proof production planning with INDUTRAX

INDUTRAX Application Environment is the perfect solution for companies that want to optimize their production planning and digitalize their production. Use real-time data, innovative positioning technologies and a flexible software structure to make your production more efficient, transparent and economical.

➡ Find out more now and take your production processes to the next level!

Software-supported production planning with real-time data: FAQ

How does the INDUTRAX software support production planning?

The software provides real-time data on locations, movements and status information from ongoing production. This provides those responsible for planning with a transparent basis for making well-founded decisions and identifying deviations from the plan at an early stage.

Is the software a classic production planning software?

No - the strength of INDUTRAX software does not lie in the automatic creation of production plans, but in the provision of contextualized real-time data that can significantly improve existing planning processes.

Can the software be integrated into existing ERP or MES systems?

Yes, the solution can be integrated into existing system landscapes via standardized interfaces and supplements them specifically with current data from the store floor.

Can I test the software or request a demo?

You are very welcome to request a personal consultation or a live demo by contacting us - we will help you with transparent advice.

Your contact person

Dr. Andreas Schürzinger

Principal Consultant IoT

Let's work together to find your optimum locating solution!

With our expertise in tracking system optimization, we analyze your specific requirements and determine the right combination of tracking technologies that can transform your production and logistics processes.Error: Contact form not found.