Our software

Optimization in shop floor management

Quick findability, events in real time and optimization of routing

Localization in production and logistics: not yet a matter of course everywhere.

Those who are unable to map the material flows of processes transparently and who tend to organize transport and supply of production on demand are wasting valuable throughput.

Efficient optimization of the material flow and elimination of sources of error cannot succeed without digital asset management.

“With the INDUTRAX Application Environment modular software system, we provide you with a unique tool. You can put it together and expand it to meet your specific needs so that your work processes are optimized down to the last detail. And always anew, based on the latest findings.”

Nicolai Karl | INDUTRAX Product Manager & Team Lead IOT | SMF GmbH

Ask us your questions about our modular software system!

Our modular software system for optimized process design

Let us show you in detail what our modular software system can do!

Optimization of shop floor management: Know what's where!

Benefit from the tangible advantages of digital process automation:

- Real-time location of objects in indoor and outdoor areas

- Detection of events and interactions of moving objects

- Recording and displaying movements (history)

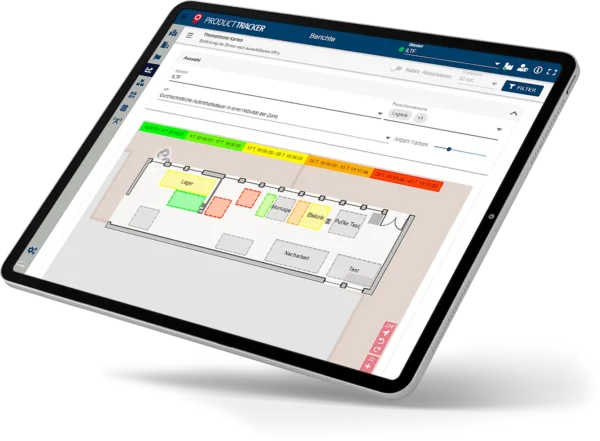

- Visualization of object positions in maps

- Detection of errors, often as they occur Finding instead of searching

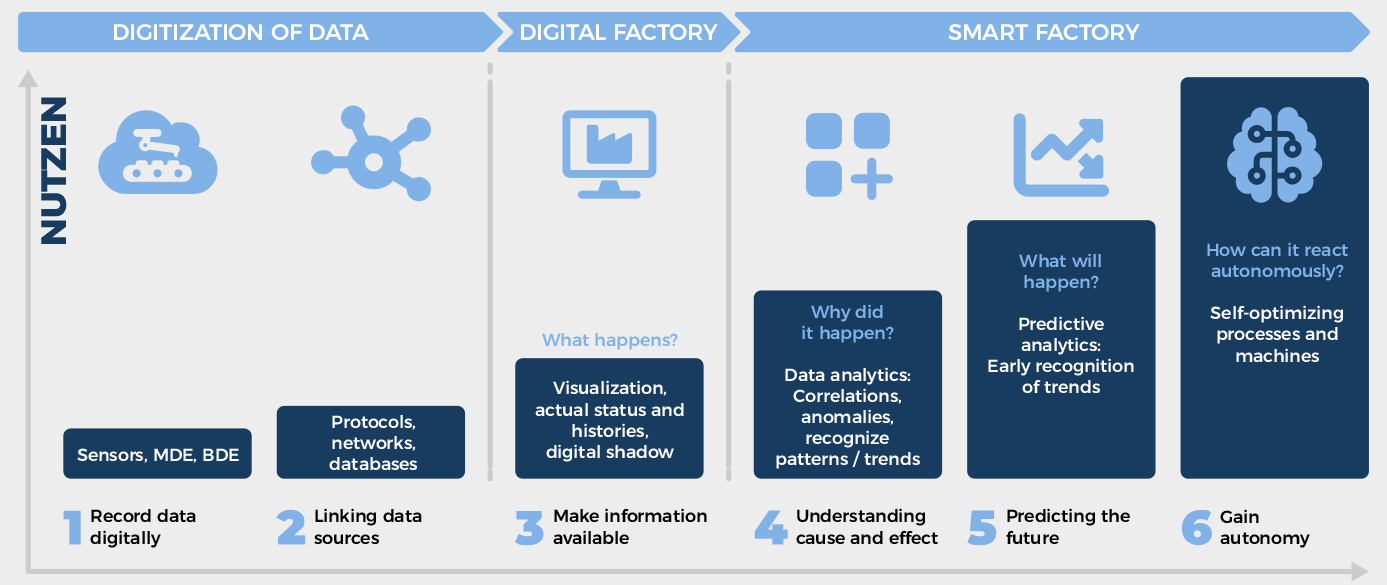

On the way to the smart factory

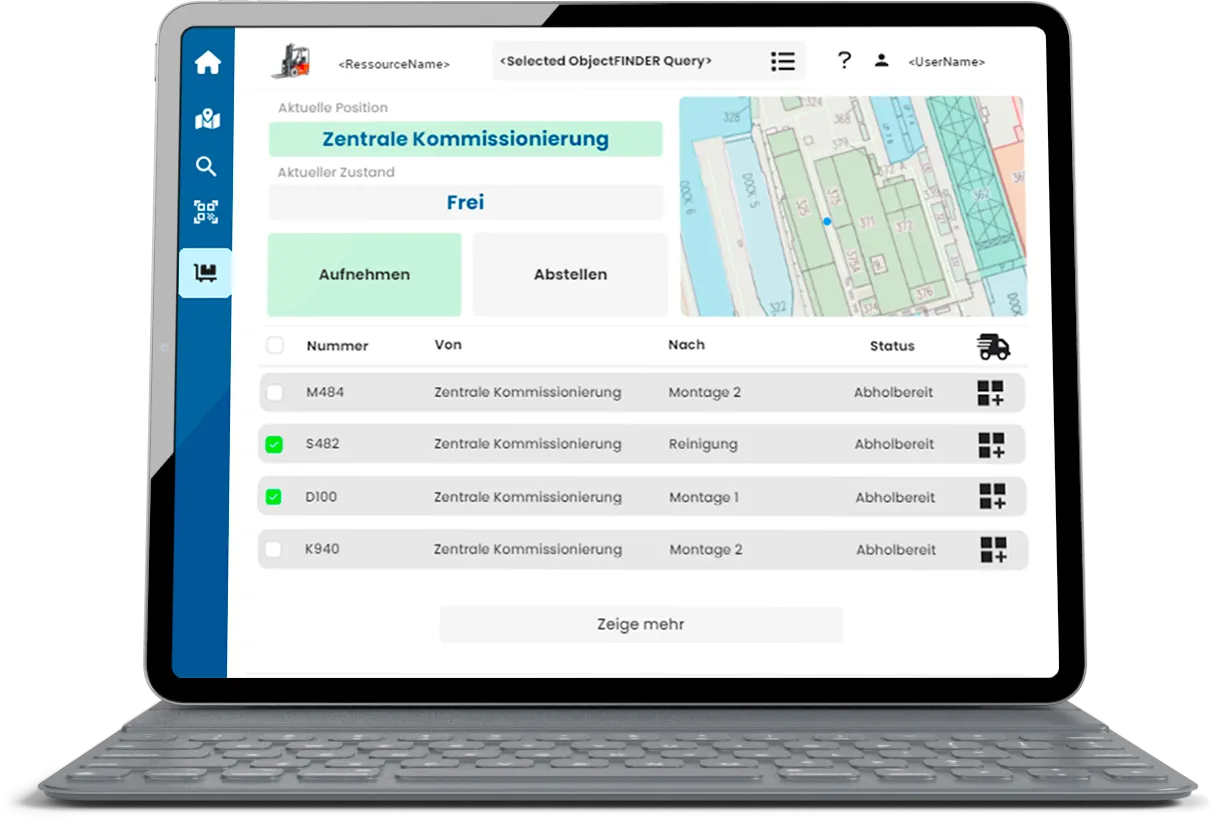

Our application is actually a location/movement/tracking software kit. This is because you not only receive information about the current location of a part, order, load or industrial truck. You also find out the routes that the objects cover and have covered. You can find out how long objects have been in place and how often they are used.

The software can do much more: it uses rules to automatically inform you of certain events - saving you manual documentation steps and revealing errors where they occur. Our customers often report significantly higher throughput after just a short time.

The result: the path from digital data acquisition to the smart factory is significantly extended in this way because all available data is correlated and evaluated - in real time. This is a continuous process of improvement: the smart factory is constantly getting smarter.

Steps on the way to the smart factory

Experience our modular software system - on site or online!

The goal: autonomous work with the software

Surely it's all totally complicated? No, it's not! We offer you predefined applications and mobile apps for common use cases in production and logistics. They contain a compilation of the required modules. Of course, we will introduce you to the use of the modular software system and are there for you if you have any questions. However, experience shows that you will be able to configure the software yourself after just a short time.

The advantages of our solutions for the shop floor:

- You can integrate all your existing systems and enterprise applications via standard interfaces or our extensive APIs.

- You can integrate and simultaneously operate various positioning and identification technologies and sensors via standard connectors.

- Raw data is plausibilized using context to achieve the required industrial reliability.

- User interfaces optimized for the shop floor are available on mobile and fixed end devices.

- Various mechanisms for deriving reliable events from plausible location data, e.g. pattern recognition based on AI

- Histories are saved - as a basis for your analyses and evaluations

- Configuration and application programming are secured by a revision system and via No Code.

- Partner-ready platform for solutions in various vertical markets and with comprehensive documentation