Optimization of processes

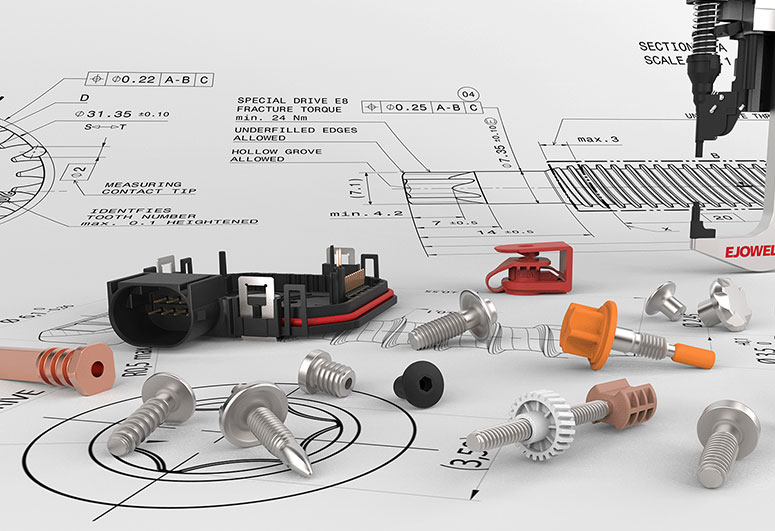

EJOT SE & Co. KG, a specialist in technical fastening and joining solutions, has achieved significant success in recent years in optimizing its production processes through the use of real-time positioning. Various fasteners are manufactured to order for industry and the construction sector at global production sites. Production takes place in several stages and often across plants.The motto “Only if the selected fastener meets the special requirements can the safety of the connections be guaranteed in the long term” requires a high degree of product variance and specific requirements for production to ensure high-quality end products.

Production and logistics processes

17

Production sites worldwide

771

million € Turnover

51

Locations

100

Years of company history

+4.000

Employees

+ 10.000

Orders active at the same time

Presence

Worldwide

The motivation

The company was looking for an end-to-end digital solution for 6 production sites that would increase efficiency by automatically tracking production orders in real time.

Manual bookings should become superfluous and search times significantly reduced thanks to mobile apps and the visualization of order movements.

The automatic updating of order data and inventories as well as integration with lean manufacturing should enable error-free, faster and optimized production control. The aim is to create seamless transparency and enable better decisions through real-time data and historical information on material flows.

The project objective

The introduction of digital worker guidance based on the INDUTRAX PRODUCTTRACKER

Find out more (personally) now!

The solution design

The introduction of digital worker guidance and automation of process documentation based on the INDUTRAX PRODUCTTRACKER application, supplemented by SAP, means comprehensive digitalization of production processes at Shop Floor.

The following technologies and systems were integrated:

Tablets and desktop PCs

Worker guidance via browser interfaces and mobile apps:

Orders to be processed are displayed on various end devices such as tablets, smartphones and desktop PCs in list and map views in the user interfaces of the PRODUCTTRACKER and the INDUTRAX mobile apps. Real-time information on position and processing status enables workers to act quickly and avoid unnecessary routes and errors.

RTLS Tags & GPS Tracker

Equipping the containers for order transports for automatic location tracking: The containers used to transport orders are equipped with Quuppa-certified BLE tags from the manufacturer BlueUp or with GPS trackers from Teltonika, thus enabling end-to-end transparency for orders in the production process. Pick-to-light functions visually guide employees to the right orders so that they can respond quickly and efficiently to production requirements and avoid unnecessary search times.

RTLS infrastructure

Indoor location tracking with Quuppa RTLS in the building:

The relevant areas within the production halls are equipped with a network of Quuppa RTLS locators, which enable the automatic detection of the locations of BLE tags. Thanks to the seamless integration of this infrastructure into the INDUTRAX software, a high reliability of the position information is achieved and the automation of work processes is supported.

SAP S/4 HANA

Automatic data synchronization with the SAP PP production control system: In exchange with the production planning and control system (SAP PP), employees have direct access to the order master data, such as order prioritization and current status. The material movements recorded by the RTLS are used to automatically trigger postings in SAP. This supports optimized process handling, error prevention is promoted and operational decisions can be made more effectively.

The solution

By integrating the INDUTRAX PRODUCTTRACKER into the existing system landscape, EJOT was able to ensure seamless recording and visualization of real-time data on production and logistics orders.

The order data is automatically transferred from SAP and merged with the position data of the tags from the Quuppa RTLS and the GPS trackers in the INDUTRAX software platform.

Thanks to the reliable preparation of position data using contextual information from the digital shadow of the factory, order movements can be continuously tracked and automatic bookings in SAP can be controlled directly by the application.

PRODUCTTRACKER’s no-code programming tools allow team leaders to automate events such as shipping notifications or order blocking, reducing workload and making administrative tasks more efficient.

- The digitalization of order tracking has significantly increased the transparency of processes.

- Sources of error have been reduced and non-value-adding activities, such as search times, have been significantly reduced.

- The solution supports sound data-based decisions that optimize material flow and enable efficient worker management.

The result & the outlook

With the introduction of the INDUTRAX PRODUCTTRACKER, EJOT achieved the following results:- Optimized overview of the status of orders in production

- Continuous increase in throughput in production

- 75% reduction in search times thanks to digital guidance for orders

- Automatic transparency of production processes

- Optimal use of resources to increase efficiency

- Avoiding errors through precise order tracking

The PRODUCTTRACKER has given EJOT a much better overview of the order status and replaced manual documentation steps with the automated solution. By recording process data, non-value-adding working times have been reduced and throughput increased. EJOT plans to expand PRODUCTTRACKER globally in the future and also integrate data from subcontractors to further increase transparency throughout the supply chain and realize the goals of Industry 4.0.

Your contact person

Experience the benefits of digitalization in logistics and production! With our tailor-made solutions, such as the INDUTRAX PRODUCTTRACKER, you can reduce errors, optimize processes and relieve your employees with efficient digital tools.

Dr. Andreas Schürzinger

Principal Consultant IoT

Find out more (personally) now!

Interested? Get in touch with us now and discover how we can take your processes to the next level together!